Engineering Expo .2014 -Ludhiana

Ludhiana - "Manchester of East" is ranked as the best place to do business in India according to a World Bank study, 2009. Many parts used in BMW and Mercedes are exclusively produced in Ludhiana. It has an established manufacturing base for engineering products comprising manufacturing units of leading brands such as Hero Cycles and Avon Cycles. It also produces 60% of India’s tractor parts.

• GDP - $4.4 billion (2009-10) • Per Capita Income - Rs. 78,171 • Growth Rate - 5.79% • Over 6,000 SMEs operating in the city and 14.45 lakh MSME units in Punjab leveraging employment to over 26.79 lakh people. • Avon Cycles distinguishes itself as the largest manufacturer exporter from India in bicycles and bicycle parts.

• Hero Cycles Limited entered the Guinness Books of World Records as the largest bicycle manufacturer in the world.

• Investment proposals of Rs.55,000 crore were signed at "Progressive Punjab" investors summit in Dec 2013. Concurrent event Powered by   Punjab Machine Tools Show

Consortium of Ludhiana

Machine Tools Manufacturers | |||||||||

Date: 12-13-14-15

December 2014

Venue: GLADA Ground, Opposite

Vardhaman Mills, Chandigarh Road, Ludhiana- 141010. Punjab. India.

Timings:

Business

Visitors: 10:00 am to 3:00 pm

General

Visitors: 3:00 pm to 7.00 pm

Showcasing Dynemech range of Anti-Vibration Mounts

& vibration damping solutions for all

machinery - Power Presses, Forging Hammers, Forging Presses, Generators,

Compressors, Fans, Crusher, CNC

machines, Lathe Machines, Textile Machines,

Tool Room Machines, &many

more.

CONTACT US for your requirements of Anti-Vibration mountings:

Proprietor: Mr. Yogesh Bansal (General Manager)

Corporate Office: 101, Priya Aptts, Opp. North-Ex Mall, Sector-14, Rohini, Delhi - 110085, India Mobile: +91-9810760131 , +91-9911145131 , +91-9212258131 Phone: +91-11-27347982 E-mail: sales@dynemech.com Website: www.dynemech.com; www.vibrationmountsindia.com | |||||||||

isolation vibration control noise isolators silent bloc silent blocs anti vibration silentbloc noise & vibration noise vibration vibration noise silent blocks av mount vibration shock fan mounts leveling foot vibrating washing machine antivibration mount

Monday, 1 December 2014

Ludhiana Engineering Expo 2014 -12 Dec to 15 Dec.2014, Glada Ground, Stall E-3 @dynemech -vibrationmountsindia.com

Sunday, 21 September 2014

VIBRATION DAMPING SHEETS regarding Honing Applications

|

| Dynemech Mounts for Honing Machines |

Honing metalworking method is a metal removing method used soon after casting, sintering, drilling, boring, or reaming to obtain precise bore dimension, geometry (cylindricity, roundness, straightness, and taper) and also surface finish. Even though with all the development of precision machining and ultra accuracy machining engineering, machining precision determines to obtain sub micron level have enhanced, chatter is still a trouble at the time of grinding which usually influences surface quality instantly and also minimizes productivity within honing machinery. It happens to be significant in high precision honing process in which a small vibration tends to make the size or surface roughness of proposed part poor, bringing about rejections, hence making vibration damping important.

DYNEMECH anti vibration PADS

1. Dynemech low natural frequency isolators damps almost all the inbound vibrations in addition to permit smooth operation.

2. Divide the actual dynamical system (generating vibratory frequencies and shocks) via its surroundings.

3. Through developing a phase difference of vibration frequency, both passive and vibration control is possible throughout honing applications.

4. Pads made of high strength material in addition to quality production processes

5. Enhanced in addition to consistent component finish, accuracy and part tolerances

FOR ADDITIONAL SPECIFICS:

Dynemech Systems Pvt. Ltd.

Email: sales@dynemech.com

Phone: +(91)-9810760131, +(91)-9911145131,

www.vibrationmountsindia.com

Sunday, 7 September 2014

Wednesday, 27 August 2014

ANTI VIBRATION MACHINE MOUNTS INJECTION MOULDING

Anti Vibration Machine Mounts

Dynemech's Injection Molding Machine Mounts provide optimum leveling and alignment of the machines within minutes, without anchoring either the machine or machine mounts to the floor. Dynemech Insulation Sheets are designed especially for injection molding and die casting machines. These vibration insulation sheets dampen both vertical and horizontal impacts found in reciprocating machines. In addition, each vibration isolation pad is engineered to possess an exceptionally high coefficient of friction that also prevents machine "walking".

Anti Vibration Mounts used extensively by OEMs and molding machine users to provide:

1. Increased equipment life.

2. Installation Savings – Machines are installed faster and easier.

3. Simplified machine installation.

4. Precision Levelling and alignment of machine mounts reduces machine wear and tear & increases tool life

5. Machine "walking" prevented.

6. Different products/customized solutions available.

7. Reduced shock and vibration.

8. Simple integration into the production plant due to flexible installation.

9. Elimination of anchor bolts. Machine can be easily re-located and Re-Levelling is much faster and easier.

10. Better Structural Safety.

FOR FURTHER DETAILS:

Dynemech Systems Pvt. Ltd.

Email: sales@dynemech.com

Phone: +(91)-9810760131, +(91)-9911145131,

www.vibrationmountsindia.com; www.dynemech.com

Sunday, 24 August 2014

Saturday, 16 August 2014

Dynemech Vibration Damper-Press Brakes

Manufacture shops are ceaselessly compelled with requests for better conveyance, enhanced quality and tighter tolerances. Furthermore the press brakes have developed into a flexible and basic apparatus for manufacture looks for both specific sheet metal work and persistent creation applications .The marriage of CNC to the machine has pushed its value considerably further. Besides, this has offered ascent to vibration damping issues with the incorporation of distinctive changed moving parts and loads of frictional and vibrational vitality. A press brake is a machine utilized basically to punch, structure, and/or twist metal. Anyway by their extremely nature, Press Brakes will create vibratory stuns and vibrations that not just influence the execution of the metal working process by likewise transmit and bother other hardware and office structures spotted in the premises. In this manner, vibration damper gets to be basic in all hardware set-ups and plants. Dynemech Anti-Vibration Machinery Shock Mounts & Vibration Damper retains and segregates vibrations - and ensures the hardware and structures in the long haul. Utilization of Dynemech Vibration Dampers deciphers into expanded security, solace, and economy.

FOR FURTHER DETAILS ON Vibration Damper contact us at:

Dynemech

Systems Pvt. Ltd.

Email:

sales@dynemech.com

Phone:

+(91)-9810760131, +(91)-9911145131,

www.vibrationmountsindia.com;

www.dynemech.com

Friday, 15 August 2014

Wednesday, 13 August 2014

Saturday, 9 August 2014

Monday, 4 August 2014

Sunday, 3 August 2014

Dynemech Anti Vibration Technology @AMTEX.2014 -25.JULY.2014 TO 28.JULY.2014

AMTEX 2014 the 9th Exhibition on

Asian Machine tools was held from 25th to 28th July 2014.

9th IndiaMART AMTEX 2014 Exhibition, organised by Triune Exhibitors Pvt.

Ltd was held in New Delhi in 2014 at Pragati Maidan. AMTEX is the

largest Exhibition covering Machine Tools and Engineering segment in

this region. Over the last 14 years AMTEX has built a reputation as the

only place to discover the latest technology, view live demonstration/s,

share ideas and most importantly secure orders.

AMTEX exhibition holds tremendous significance for all levels in manufacturing organizations – be it CEO's & entrepreneurs, senior executives, corporate planners & strategists, manufacturing managers & executives, shop-floor engineers & technicians, agents & dealers, spanning all manufacturing industries.

Dynemech showcased it's entire range of ANTI VIBRATION MOUNTS.

More snippets can be seen here.

We provide complete vibration damping solutions ranging from Circular Mounts, Wedge Mounts, Vibration Insulation Plates, Rubber Air Springs, Machinery Raiser Damping Blocks, Rubber Sheet/pads,

Levelling Mount, Rubber And Rubber Metal Bonded Vibration Isolator, Spring Vibration Isolators, Levelling Mounts, Cup Mount, all type of Machine Mounts , Cushyfoot mountings, Shock And Vibration Isolators, to Foundation Isolation/ Insulation for all types of machine tools. We also provide tailor made solutions besides providing wide product range and quick installation service.

We enjoyed the many inspiring conversations, and were overwhelmed with response to our new product launched -Shock Isolator For Forging Hammers.

Study our complete range of Anti Vibration product catalog

We thank you once again for you visit and hope that we could begin a mutually benefitting business relationship for the future !!

Dynemech Systems Pvt. Ltd.

101, Priya Aptt., Opp. North Ex-Mall, Sector-14, Rohini, Delhi-110085

E-mail: sales@dynemech.com

Phone: +(91)-9810760131, +(91)-9911145131,

http://www.vibrationmountsindia.com

AMTEX exhibition holds tremendous significance for all levels in manufacturing organizations – be it CEO's & entrepreneurs, senior executives, corporate planners & strategists, manufacturing managers & executives, shop-floor engineers & technicians, agents & dealers, spanning all manufacturing industries.

|

| Dynemech range of Anti Vibration Products on showcase |

|

| Dynemech Stall in AMTEX.2014 EXHIBITION |

|

| Visitors @ Dynemech stall in AMTEX Expo in Pragati Maidan, Delhi |

|

| Vibration Dampers on display |

|

| Anti Vibration Products |

More snippets can be seen here.

We provide complete vibration damping solutions ranging from Circular Mounts, Wedge Mounts, Vibration Insulation Plates, Rubber Air Springs, Machinery Raiser Damping Blocks, Rubber Sheet/pads,

Levelling Mount, Rubber And Rubber Metal Bonded Vibration Isolator, Spring Vibration Isolators, Levelling Mounts, Cup Mount, all type of Machine Mounts , Cushyfoot mountings, Shock And Vibration Isolators, to Foundation Isolation/ Insulation for all types of machine tools. We also provide tailor made solutions besides providing wide product range and quick installation service.

We enjoyed the many inspiring conversations, and were overwhelmed with response to our new product launched -Shock Isolator For Forging Hammers.

Study our complete range of Anti Vibration product catalog

We thank you once again for you visit and hope that we could begin a mutually benefitting business relationship for the future !!

Dynemech Systems Pvt. Ltd.

101, Priya Aptt., Opp. North Ex-Mall, Sector-14, Rohini, Delhi-110085

E-mail: sales@dynemech.com

Phone: +(91)-9810760131, +(91)-9911145131,

http://www.vibrationmountsindia.com

Thursday, 19 December 2013

Dynemech Lathe Leveling Jacks and Levelling Mounts

|

Lathe Machinery Mounts to isolate all Industrial Metal Working Machinery |

Lathe machinery is one of the most important machine tool in

manufacturing industries. Interaction

between motors, pulleys, sheaves, chuck and gears cause vibrations in all CNC lathes

and Lathe machinery. Besides, self-excited chatter is a basic performance

limitation in the machining of metals in all

heavy duty lathe machines, requiring Dynemech Leveling Mounts to

optimize performance.

|

| WEDGE ACTION VIBRATION DAMPERS |

Moreover, Lathe machine tools are

liable to deterioration in their performance level with respect to time due to

various causes such as wear and tear, ageing, unbalance, looseness of parts

etc. and produce a corresponding increase of the vibration level. So, better

vibration damping and vibration isolation with leveler anti vibration jacks and

vibro mounts becomes imperative. Add to this the high vibration frequencies due

to belt tension fluctuations, gear tooth frequencies at the mating gears,

defects in bearing and unwanted vibrations due to unbalance rotors. All the

vibration related problems are addressed when Lathes are installed on Dynemech

Lathe leveling jacks and vibration damping leveling mounts.

|

No Vibration Transmission-Lathe Machinery Mounts |

Machine tool vibration in CNC lathes and heavy duty lathes, if uncontrolled,

can adversely affect the surface finish, dimensional accuracy and tool life.

About 70% of the failures in the machine tool could be due to increased disturbing

vibration level of the machine leading to production failures and maintenance

issues. Dynemech Lathe leveller jacks and leveler feet for lathe offers

economical solutions to such critical and costly production issues.

|

Heavy Duty Lathe Machine Fixators and Anti Vibration Mounts |

|

Precision Leveling Jacks for accurate alignment of Long Bedded Lathes |

Lathes having heavier stands are better at dampening the vibrations.

But, even strong, cast iron bases, because of their inherent metallic

structures, are not always adequate by themselves at damping vibrations

generated during the machining operations. For these Leveling plate for lathes –elastomeric

leveling jacks , spring viscous leveling mounts or pneumatic vibration dampers

or leveling jacks are required. Reducing or damping vibration in a lathe is

important for several reasons. It is imperative for more precise machining by

allowing greater dimensional control, leading to improved surface finishes on

the machined part and allowing faster machining speeds and heavier or deeper

cuts.

All these attributes can be obtained by precise leveling and accurate

alignment of lathes on Dynemech Leveling Jacks and Machinery Mounts. Reduced

vibration also increases reliability and tool/machine life and can reduce noise

from the machining operation.

|

PRECISION LEVELERS AND FIXATOR MACHINERY JACKS |

Vibration damping can be defined as the capacity of a mechanical system

to reduce the intensity of a vibratory process. Dynemech vibration isolation

solutions and leveling jacks lead to reduction of intensity of undesirable

resonances; acceleration decay(settling) of transient vibration excited by

abrupt changes in motion parameters of mechanical components; prevention or

alleviation of self-excited vibrations; prevention of impacts between vibrating

parts when their amplitudes are reduced by damping; potential for increase in

efficiency due to reduced peak vibratory velocities of components having

frictional or micro impacting interactions; reduction of noise generation and

of harmful vibrations transmitted to human operators and surrounding building

structures.

|

| Vibration Control in Lathes installed on Dynemech Anti Vibration Mounts |

The primary effect of increased damping in a structure through leveleing

jacks and leveling feet is a reduction of vibration amplitudes at resonances,

with corresponding decreases in stresses, displacements, fatigue and sound

radiation.

|

| Vibration and Levelling of Lathes mounted on DYNEMECH's Vibro Dampers |

DYNEMECH range of anti vibration machinery mounting systems including

wedge action leveling jack and machinery leveling shock mounts isolate all

kinds of vibration generated in the machinery and also buffer the machine

against vibrations travelling from the surrounding environments to the machine

itself.

|

| Elastomeric AV Mounts for Vibration and Noise control |

Dynemech Wedge Jacks and machinery leveling

shock mounts, Series DT are designed for machines which are top heavy or have

eccentric motion or machines which must be anchored to the ground. They can be

used without insulation plates or lathe rubber pads for precision levelling and

alignment in all spatial axes along with centric

anchoring. Series DTO with single center hole improve alignment accuracy,

rigidity and stability in long bedded machinery both with and without machinery

rubber feet.

|

| CNC Lathe machine installed on Antivibration Mounts for Vibration Control |

|

Vibration and Shock Control Leveling Jacks for CNC Lathe Machinery |

Dynemech Leveling Foot Mounts VHS Series is

used for precision leveling and aligning machinery to very strict tolerances

and makes it possible to vary adjustments at any time, even under maximum loads

requiring only a small hand wrench to adjust.

|

| Vibration Control in Heavy Duty Lathe Machines |

Dynemech's Lathe Machinery Leveling Jacks DTH Series mounts are designed for Lathe machines

which require high height adjustment and critical precision levelling and

alignment. They have a large leveling range with sturdy dimensional parameters.

Dynemech

Lathe shock mounts TPM Series Mounts have a height of 100mm/150 at mean position to help

proper cleaning and repairing under the machine as per TPM guidelines for

machine installation by IMTMA. Vibration reduction is possible through

assembling respective Dynemech insulation plates.

For further details contact :

Dynemech Systems Pvt. Ltd.

Ph:9810760131,9911145131

www.vibrationmountsindia.com

Just wanted to wish you all a Merry Christmas, Happy Holidays, or a Happy whatever you are celebrating at this time of year.

The Dynemech Team

The Dynemech Team

End to Vibrations in Injection Moulding Machines

The noise and vibration problems created by injection moulding

machines can be moderated by the installation of vibration absorbers. The

composite material insulation plates help in energy absorption and reduction of

noise and vibration.

Vertical

adjustment wedge mounts are ideal solutions for precise, accurate, efficient

and economical machinery levelling and installations.

Besides,

vibration reduction and vibration isolation other benefits availed are:

ü

Rugged heavy duty construction of the mounts

with varied load carting capacities

ü

Precise levelling with easy and smooth adjustment

ü

Enhanced machine stability as machine bolted to

vibration reduction mounts.

ü

Relocation of machinery possible as no grouting

or bolting necessary.

ü

“Machine

Walking” prevented as per OSHA requirements.

|

Injection Moulding Mounts |

For

further details contact :

Dynemech Systems Pvt. Ltd.

Ph:9810760131,9911145131

www.vibrationmountsindia.com

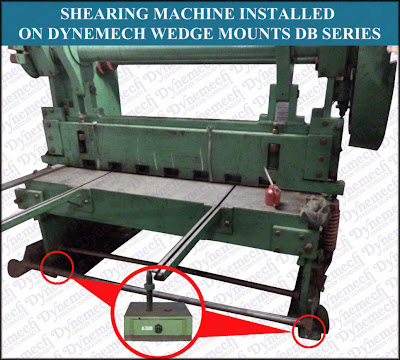

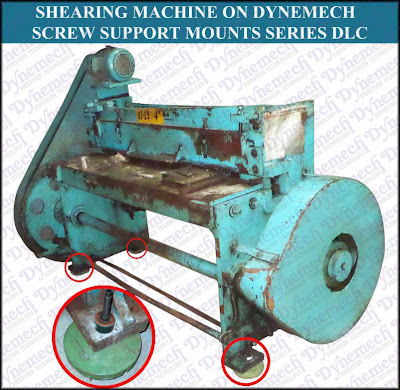

Machine Vibration Pads - Vibro Damper Pads for Shearing Machines

Shearing, also

known as die cutting is a process which cuts stock without the formation of chips or the use of burning

or melting. Such impact generating machines inherently suffer from unwanted

vibrations thus, necessitating the need for Dynemech Vibro Dampers.

Machining

and Shearing operations like blanking, piercing, roll slitting, and trimming are

invariably accompanied by relative vibration between work piece and tool. These

vibrations can be due to inhomogeneities in the work piece material;

disturbances in the work piece or tool drives; dynamic loads generated by

acceleration/deceleration of massive moving components; vibration transmitted

from the environment(passive vibration transmission); self-excited vibration

(active vibration transmission) generated by the cutting process or by friction

(machine-tool chatter). Modern Installation technique entails installation of equipments on VIBRO

DAMPERS to protect from shock and vibrations which are inherent in all manufacturing

environments. Dynemech Vibro Dampers are highly efficient, proven and

economical vibration and shock isolators.

The tolerable

level of relative vibration between tool and work piece, i.e., the maximum

amplitude and to some extent the frequency, is determined by the required

surface finish and machining accuracy as well as by detrimental effects of the

vibration on tool life and by the noise which is frequently generated. Machine performance is critical to high

product quality, in the current business scenario. Hence, new manufacturing

plants and also old plants in various stages of upgradation do not accept

excessive tolerances & imprecise control of their production systems. Dynemech

Vibrodampers and vibration isolation systems have become essential part of currents

modern industrial plants. All types of machines & equipment are installed

on custom made, yet economical elastic foundations comprising of either elastomeric

vibrodampers, spring viscous vibrodampers or pneumatic vibro dampers.

These damaging impact vibrations will cause

accelerated wear and premature failure and necessitate corrective action to

ensure profitable productivity. Moreover, vibrations generated by the shearing

machines may adversely affect the building and the adjoining structures and

hamper adequate working of nearby machinery. Dynemech anti vibration solutions with

extensive experience and technical back up and confidence gained over many

successful installations, helps achieve best precison machinery installation with

maintenance-free operation of all production machineries. At the same time,

Dynemech vibrodampeners drastically reduces vibrations in the surroundings building

and structures creating comfortable work environment for plant and surrounding

buildings or industrial units.

The overall vibration damping capacity of a

structure with cast iron or welded steel frame components is determined only to

a small extent by the vibrodamping capacity of its individual components. Vibration

damping and vibro isolation can be increased without impairing the static

stiffness and machining accuracy of the machine by the use of Dynemech

vibration dampers, Series DB/DF and dynamic vibration absorbers like spring

isolators.

Dynemech

tuned dynamic vibration absorber and vibro dampeners has been employed

with considerable success on milling machines, machining centres, radial

drilling machines, gear hobbing machines, grinding machines, shears and boring

bars.

Dynemech Vibration isolation

solutions dampen vibrations by varied means to ensure excellent vibration

control, reduction in foundation size, flexibility in plant layout, accurate

alignment and precise leveling & lowering of machinery and tooling

maintenance.

• Dynemech vibrodampers engineering ensures Force

Reduction of excitation inputs due to, for example, unbalance or misalignment, will

decrease the corresponding vibration response of the system.

• Tuning (changing) the

natural frequency of a system or component will reduce or eliminate amplification

due to resonance when installed on Dynemech vibration isolation mounts or

vibrodampeners.

• Vibro Dampers provide Vibration Isolation as

they rearrange the excitation forces to achieve some reduction or cancellation.

• Vibration Damping is the conversion of

mechanical energy (vibrations) into heat through the use of Vibro Damping

Sheets.

For further details contact :

Dynemech Systems Pvt. Ltd.

Ph:9810760131,9911145131

www.vibrationmountsindia.com

Wednesday, 18 December 2013

Because of the features such as short

processing time, high productivity, and high accuracy, high-pressure die

casting is most widely used in most manufacturing processes in the automobile

industry, to increase the amount of production year by year.

Die casting is a metal casting process

that is characterized by forcing molten metal under

high pressure into a mould cavity. But, the casting equipment and

the metal dies represent large capital investment and this tends to limit the

process to high volume production.

So, to ensure minimum production loses,

to improve production efficiency and reduction of wear and tear of dies and tooling,

we need to protect the machines from vibrations through Dynemech Isolation

Mounts.

Our Vibration Pads allow the following benefits:

ü Fast

, Easy and Inexpensive Installation - even on working machines with minimal

down time.

ü Flexible

Shop Floor Plan due to ease in machine relocation - Permanent mobility of

machines.

ü Better

Structural Safety of building and adjoining structures.

ü Undesirable

Vibration and Noise Reduction.

ü Installation

of Sensitive Equipments near dynamic machines in the same workshop.

ü High

precision levelling and accurate alignment possible.

ü Mounts

are made with high strength materials and high quality production processes;

zero or minimal maintenance required; lifelong service.

ü Wide

range of anti vibration solutions to suit almost all industrial applications.

ü Composite

nitrile rubber insulation plates resistant to moisture, almost all kinds of

fuels, lubricating oils, acids etc. used in the shop floor.

ü Unique

cell design and high coefficient of friction facilitates good adherence to the ground.

For further details contact :

Dynemech Systems Pvt. Ltd.

Ph:9810760131,9911145131

|

Vibromounts - Pressure Die Casting Machines |

Saturday, 16 November 2013

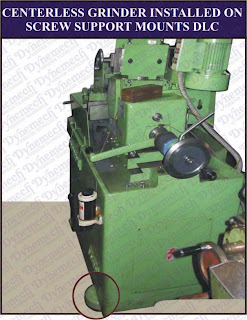

Vibration control in Precision Centerless Grinders

|

Vibra Mountings -Anti Vibration Mounts |

Centerless grinders are

one of the most common tools used in manufacturing. These machines are used to

remove material at a steady yet slow pace through the process of grinding.

Centerless Grinding is equipped to grind a wide variety of studs, pins,

bolts, screws, bushings, and other parts from a full range of materials. These

machines are commonly found in manufacturing settings in aircraft, aerospace, defence,

hardware, electronics, automotive, marine & medical industries.

|

Centerless Grinder On Dynemech Vibra Mounts |

It’s the relationship

among these three basic components—grinding wheel, regulating wheel and work

blade—that makes the difference between a successful centerless grinding

application and one that gives headaches and bad parts. But, it is the same

interaction that gives rise to undesirable vibrations leading to uneven surface

finish, problem of chatter and rejection of job lots and overall loss of

production efficiency. Unbalance in spindle-collet combine, grinding wheels,

motors , bearings ,presence of outside vibration all affect the precision

grinding process. The use of centerless

grinding has now a days become imperative in shops involved in high volume

production runs.

|

Grinders -Vibration Isolation |

Forced vibration from

machine rotating elements and self-excited vibration produce a relative radial

movement between the wheel and work piece during grinding and the wheel and

diamond during dressing, causing errors in work piece finish and form. By controlling

vibration produced during the grinding and wheel dressing operations a measure

of expected work piece accuracy and quality can be obtained.

|

Anti Vibration Pads For CNC Grinders |

Over the years, Dynemech

has successfully isolated all kinds of passive vibration ie. vibrations coming

to the centerless grinder from other impact and rotating machines of the shop

floor and/or from other nearby sources. Our anti vibration solutions provide a

unique combination of value, precision, productivity and practical usability.

They also provide protection from vibrations transmission from the machines to

nearby sensitive equipments and machines, to suspended floors, walls and

buildings.

|

Centerless Grinding Machinery Mounts |

Dynemech has engineered

different anti vibration solutions for centerless grinding machine depending

upon the environments they are being installed in. Some of the scenarios are:

|

DYNEMECH Precision Leveling Mounts and fixators |

VHS with Dh insulation plate

Precision Levelling Mounts - Series VHS mounts provide

precise levelling and alignment. The top spherical plate of VHS Series

compensates for the angular difference between the machine base and the floor.

The body of the mount can be anchored to the floor to keep the mount positioned

during installation of machines over Series VHS. The levelling can them be done

after that. VHS Series mounts can be anchored to the floor or can be used as

free standing elements. VHS series wedge combined with Dh insulation plate provided

high stability along with vibration reduction.

|

CNC Machine- Vibra Mounts |

|

Leveling Jacks for Grinding Machines |

|

Vibration Control in Grinding Machines |

Our wedge mounts, Series DB

with Ds2 insulation plate is most suitable for centerless grinding machines as

it dampens vibration transmission from the machine to the floor and to the

surrounding measuring instruments. It also damps vibrations coming from outside

impact and rotating machines to the centerless grinder.

|

Vibration Damping Insulation Plates |

For critical applications like centerless machine

installation on suspended floor, during start up of the machine, the floor may

vibrate with high amplitudes. Also, in scenarios wherein high velocity, and

high amplitude shock waves are being transmitted from a power press or forging

hammers, air springs or vibration isolating insulation plates may be used.

For more details about Anti-Vibration mounts kindly contact us:

Subscribe to:

Posts (Atom)