|

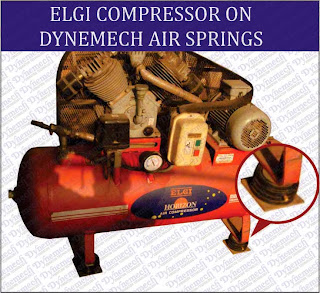

| Anti-Vibration Pneumatic Mounts for ELGI compressor installation |

unbalance in rotating parts, worn or bent gears, damaged bearings, misaligned couplings or bearings,

electromagnetic forces, etc.In compressors, however, the most common causes of vibration are unbalance in rotating/ reciprocating parts and abnormal aerodynamic forces. Vibration is a form of wasted energy that reduces the efficiency of the compressor and leads to greater vibration emissions.

|

| Compressor installed on Pneumatic mounts for vibration isolation |

Compressor installed on Pneumatic mounts for vibration isolation

Compressors are most commonly used applications in refrigeration systems, air conditioning units and

compressed air filling systems.

|

| Vibration Control in 50 H.P. Compressor installed on Dynemech Spring Isolators |

|

Dynemech Vibration Damping Insulation Plates |

|

| Vibration Damping for Compressors on Series DML |

|

| Vibration Control in Compressors on Dynemech Screw Support mounts with Levelling Adjustment |

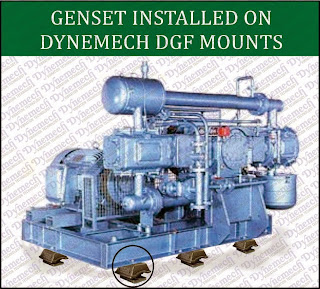

In compressors, generators, pumps, and blowers low frequency vibration caused by flow instabilities create excitations in the supporting structures. This leads to damage to near by industrial applications and buildings. Moreover, high residual frequency vibrations caused by various rotating equipments running at varied natural frequencies may result in resonance in compressor body. Avoiding this becomes imperative for successful running of compressor units at any profitable efficiency parameters.

DYNEMECH anti vibration pads and mounts relieve stresses on the equipments thereby reducing maintenance costs. Also, it improves ambient environment contributing to a more comfortable and productive workspace. Attention to a relatively small, inexpensive vibration isolator during initial installation of compressors could prevent much more costly trouble later.

Elastomeric Mounts, Series DLK are versatile,compact and inexpensive effective vibration dampers.

|

COMPRESSOR ON Series DLK |

dimensions, robust design and excellent performance.

|

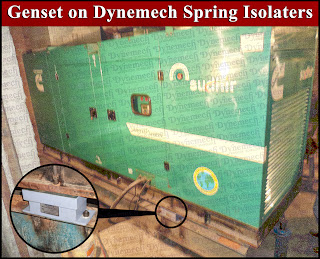

Flexifoot for Generator Support and Vibration Damping |

industrial equipments upto 80-95%.

|

High dynamic vibration damping |

No comments:

Post a Comment