|

Dynemech Anti Vibration Pads for Pressure Die Casting Machines |

Pressure

diecasting is a process in which molten metal is introduced into a metal mould

or “die”, and is subjected to pressure in order that it shall conform to the

exact shape of the mould impression or “die cavity”.

Die

casting has progressed over the last fifty years from relatively small parts

made from lower melting metals and alloys such as zinc, to today’s casting of

very large parts, such as engine blocks.

As die

casting conditions grow more

severe in temperature, pressure and increased part size, increase

movement-clamping arrangements the need arises for vibration isolators to

enhance the die casting process, by providing precision levelling, alignment

and vibration control.

|

Pressure Die Casting Machine On Dynemech Isolator Mountings |

|

Dynemech Rubber Anti vibration pads |

Dynemech

anti vibration solutions help die casters to continue to advance their

operational efficiency and lower their production costs, even as the industry

faced increasing challenges for more part complexity. An increasingly high-tech, sophisticated manufacturing

method capable of superb, repeatable quality, and high production rates through

new die steels, faster die-making, computer controls and robotics can sustain

only when supported on resilient anti vibration elastomeric pads. Vibration

control thereby

·

increases quality

production

·

reduces scrap

costs

·

improved die

life, resulting immediately in longer production runs from an initial die

investment

·

reduced price per

piece and total life cycle costs.

|

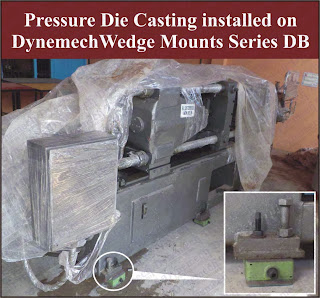

Pressure Die Casting installed on Dynemech Wedge Mounts, Series DB |

Ruggedly

designed rubber mounts feature varied height adjustments and anchor free

flexible installation keeping the option of relocation of machinery open. Multiple

wedges and Dynemech insulation plates are interlocked and assembled so that

they are well suited for all applications with high horizontal forces. Besides

imparting solidity and rigidity as machine foots they provide minimal lateral

flexibility to avoid machine movement and thus mitigate vibration

transmissibility.

Precise

levelling features of Dynemech Wedge Mounts Series DF/DB ensures that the die

faces close properly, decreasing wear and tear and productivity and maintenance

issues from cropping up every now and then. The chequered cell design of the

composite material insulation plate provides skid and shock resistance besides

vibration control.

- · No machine walking

- · Variable height adjustments possible

- · Uniform weight distribution and precise alignment

- · Flexible and quick machinery installation

- Uniform distribution of uneven weights and best fitments in base square housing are some of the complimentary features that ensure ideal machinery installation.

For more details about Anti-Vibration mounts kindly contact us:

Vibration pads are certainly a good way to go. I've used them in past and they've helped a lot. I am interested to know how well shocks might work, though. Thiago | http://www.missionsupplyonline.com

ReplyDelete