It is from the ground up that a smoother weave is

created.

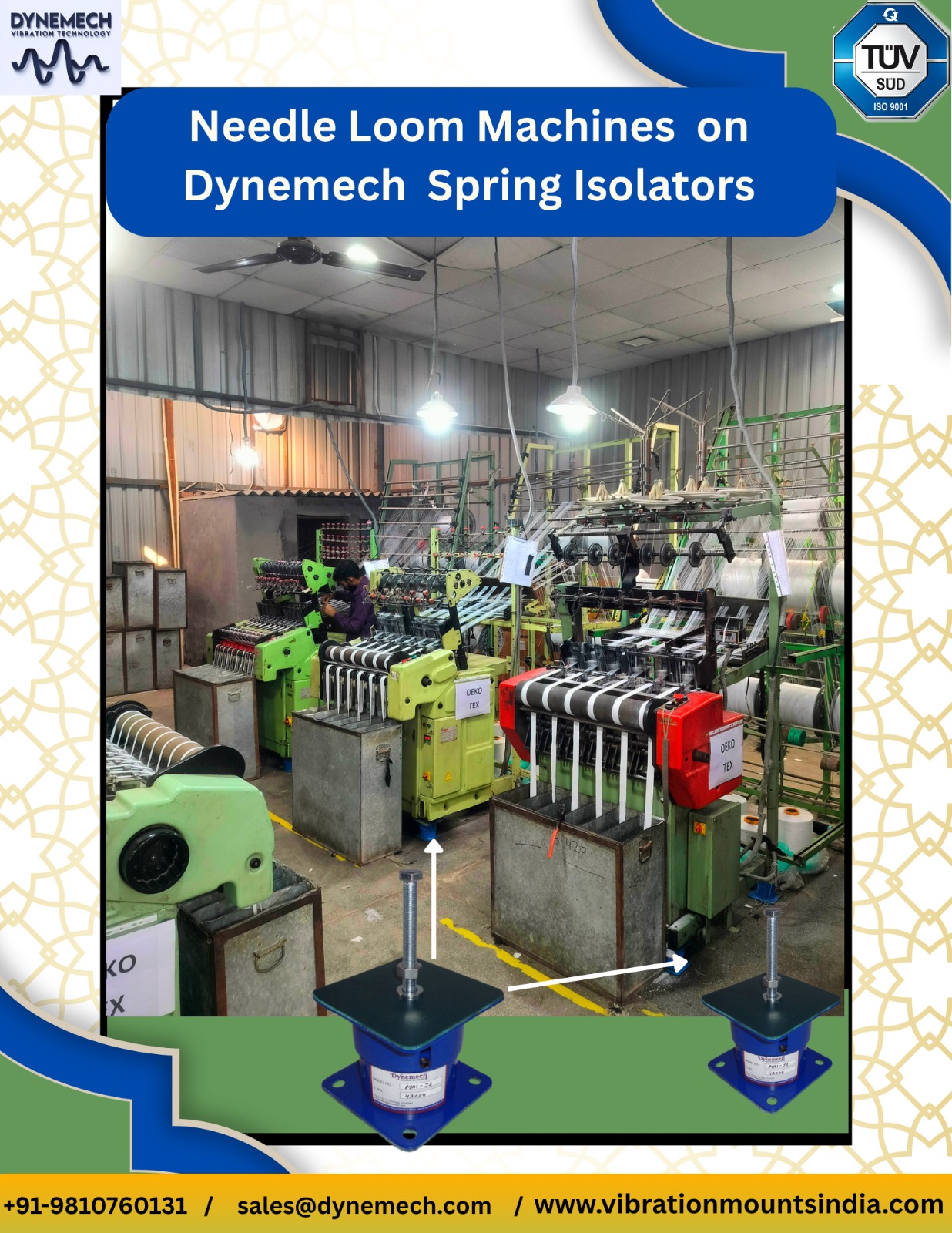

Precision is of the utmost importance in the construction of textiles. In

addition, while you are using high-speed needle loom machines, even the

slightest vibration can cause things to go awry, ranging from the quality of

the stitches to the longevity of the machine.

The reason for this is that an increasing number of manufacturers are switching

to Dynemech Spring Isolators,

and they are noticing the difference almost immediately.

Are you aware of what is actually taking place beneath your machine?

Vibrations are produced by a needle loom each and every time it is used, but

especially when it is being started up or shut down. In addition to being a

nuisance, these can cause the parts to misalign, speed up the wear on the

parts, and have an effect on the consistency of the cloth.

Because of this, Dynemech Anti

Vibration Technology is a thing.

When it comes to providing your machine with the appropriate natural frequency,

our Dynemech Spring Isolators

are designed to do just that. And why is that so significant?

The reason for this is that it causes a phase difference

between the vibrations that your machine generates and the vibrations that your

floor may reflect back upon itself. This results in less rattling and more

control over the situation.

In addition, the secret component is Viscous

Damping.

Imagine a cushion that not only absorbs the shock, but also controls the amount

of bucking that your machine does during challenging situations such as ramping

up, shutting down, or with each stroke of the hammer.

It is the marvel of Viscous Damping

that this occurs. It maintains the stability of your machine even when it is

operating at a speed that is close to its resonance point, which is the speed

at which vibrations typically become uncontrollable.

The use of damping avoids excessive motion that would otherwise harm the

machine and the floor, regardless of whether the mechanism in question is a

loom, a press, or a hammer.

What is the reward?

The weaving is smoother and more precise, the factory floor is quieter, the

equipment has a longer lifespan, the installation and alignment process is

simplified, and there is no need for deep foundations or grouting.

Explore Our Full Range of Solutions: https://www.vibrationmountsindia.com/products/

#Dynemech,

#SpringIsolators, #NeedleLoomMachines, #AntiVibrationTech, #ViscousDamping,

#MachineDynamics, #SmartManufacturing, #TextileMachinery, #VibrationControl,

#PrecisionWeaving, #IndustrialEngineering, #WeavingInnovation, #MadeInIndia

Contact Us: +91-9810760131

Email: Sales@dynemech.com

Discover Now: vibrationmountsindia.com

No comments:

Post a Comment