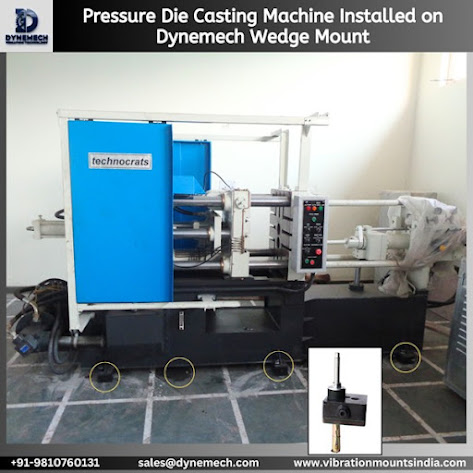

We are proud to announce that we have successfully installed

a Pressure Die Casting Machine on Dynemech Wedge Mounts, confirming us as a reputable

provider of dependable, vibration control and precision levelling products

within the manufacturing community.

Pressure Die Casting is a high speed method of casting where

molten metal is injected into a cavity at high speeds and pressure. The

mechanical precision and repeatability of the process depend not only on the

design of the Die Casting machine, but also on the stability and alignment of

the machine because even the smallest vibration or misalignment can affect the

product quality, tool life and maintenance

Dynemech DL/DLS Series Wedge Mounts are ideally suited to

these applications, being designed for heavy-duty industrial machinery where

solid support, precision levelling and vibration isolation all have to be

achieved.

Why Dynemech Wedge Mounts Are Ideal for Die Casting

Applications:

- Robust

Construction: Dynemech Wedge Mounts are built to withstand the dynamic

loads and operational stress generated during high-pressure casting

cycles.

- Accurate

Levelling: The integrated levelling system allows for easy and precise

adjustment, ensuring correct machine alignment without the need for

foundation anchoring.

- Enhanced

Stability: The wide base area and non-slip design provide exceptional

grip and stability on shop floors, even during continuous, high-pressure

operations.

- Vibration

Isolation: Our mounts significantly reduce the transmission of

vibrations to surrounding structures and equipment, protecting nearby

machinery and enhancing overall production quality.

- No

Foundation Required: Machines can be installed directly on the shop

floor without grouting, allowing flexibility in layout and easy relocation

when needed.

This installation has improved operational efficiency of the

machine, but has also reduced the setup time, maintenance time, and issues with

floor vibrations the customer was experiencing in the long term.

Engineering Confidence, One Installation at a Time

At Dynemech, we recognize that each application is an

individual case. We consistently work closely with each customer to advise on

the best vibration control solution for the application based on the type of

machine, the loading condition, and the plant environment. Our products allow

manufacturers to achieve increased precision, reliability, and productivity,

which are all key advantages in today's industrial environment.

We are happy to have completed another successful

installation in the current foundry and die-casting sector by providing new

mounting and isolation technologies.

Dynemech Wedge Mounts offer unmatched level support and

level performance for pressure die casting machines, CNCs, injection moulding

machines, compressors, or any machinery needing constant level performance..

🔗 To learn more about our

products: https://www.vibrationmountsindia.com/products/

No comments:

Post a Comment