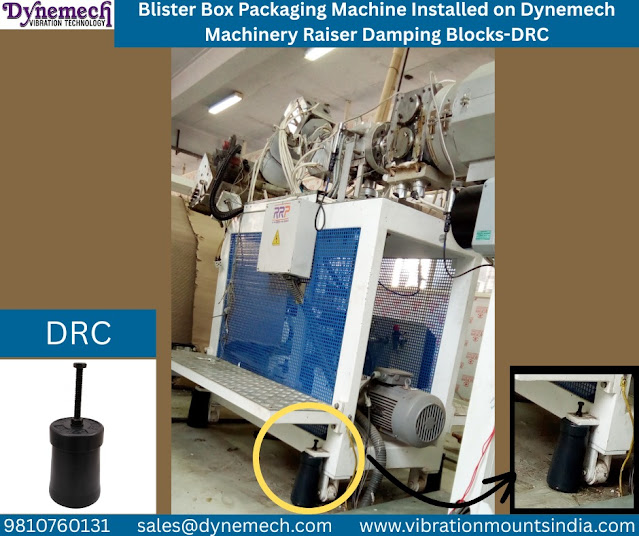

Blister Box Packaging Machine Stabilized with Dynemech’s DRC Series Anti-Vibration Blocks

The Ground Blister Box Packaging Machine Mounting on Dynemech's DRC Series Machinery Raiser Damping Blocks is the first step towards smarter Packaging.

We take it literally when we say that every outstanding Packaging line starts

with a good foundation. It wasn't only about putting a high-speed Blister Box

Packaging Machine atop Dynemech's DRC Series Machinery Raiser Damping Blocks

for the first time. It was about getting improved performance, smoother operations,

and long-lasting dependability.

In automated packing, even the smallest Vibration can cause big problems, such

seals that aren't lined up well, blisters that don't work, or Machines that

wear out too quickly. That's why our DRC Blocks are so vital. They not only

keep your Machines running smoothly, but they also keep your production,

uptime, and sanity stable.

DYNEMECH MACHINERY RAISER DAMPING BLOCKS offer easy and quick installation of CNC Machines. These blocks offer both levelling and Vibration damping besides raising height of the Machine for proper cleaning and repairing under it.

Raiser Damping Blocks are assembled with insulation plates for Vibration reduction. Ideal for CNC Turning/ Machining Centres, Cylindrical & Centreless Grinding Machines, Precision MachineTools. Help implement TPM norms for machine installation.

Proper maintenance, cleanliness, Vibration reduction results in enhanced machine tool reliability (zero breakdowns), reduced operation and life cycle costs which are the driving factors for adoption of Total Productive Maintenance (TPM) practices.

Machines are installed at a height of 100-150 mm which help implement TPM norms for machine installation. Series DRC are suitable for Machines having plain hole in the base. Levelling is done by turning the bolt which lifts the cover plate along with the machine. Available both in 100mm height.

Application: Tool Room Machines, Plastic Injection Moulding Machines, Pressure Die CastingMachines, Shaper, Printing and Textile Machines etc.

This Setup Makes Sense for These Reasons:

1. A Strong Base for Precision Machines

Blister packing Machines are picky; they need to be stable to work right. Our

DRC Blocks maintain them level and steady, even when they are running at

tremendous speeds.

2. Quietly Getting Rid of Vibration at the Source

Our DRC Series uses smart dampening materials that soak up Vibrations before

they may hurt your Machines (and the quality of your packaging).

3. Fewer Breakdowns, More Work Done

Equipment lasts longer when Vibrations are kept to a minimum. You pay less for

upkeep and more to have the job done.

4. Always the Same Quality

A constant setup means perfect sealing, perfect alignment, and fewer rejected

packs. This is a big plus, especially in industries like pharmaceuticals and

fast-moving consumer goods.

5. Simple to Set Up and Change

Floors that aren't level? No problem. You can change the height of DRC Blocks,

which makes it easier and faster to set up the machine. This way, your staff

can get back to running instead of mending.

Made for the Real World

We don't just make Vibration control solutions at Dynemech; we also make sure

your equipment works well. This installation is another example of how our DRC

Blocks help Packaging professionals get more done with less stress. It's all

about better support, easier operations, and clear heads on the work floor.

To learn more about our products: https://www.Vibrationmountsindia.com/products/

#Dynemech, #DRCBlocks, #BlisterPackaging, #PackagingMachinery, #VibrationControl, #SmartManufacturing, #AntiVibrationMounts, #MachineryLeveling, #PackagingSolutions, #ProductionEfficiency, #StableMachinery, #AutomationSupport

Contact Dynemech Systems Pvt. Ltd.

+91-9810760131

sales@dynemech.com

No comments:

Post a Comment