For modern manufacturing, exactly how apt this could go is

that precision, stability, and efficiency are primary pillars of any

manufacturing process in order to assure consistent quality of products and the

best performance of machines. One very critical yet again often neglected

factor ensuring smooth operation is machine mounting. Poor mounting or

foundation on which even the most sophisticated Injection Moulding Machine is

placed can create such problems as misalignment, excessive vibrations, and

uneven load distribution.

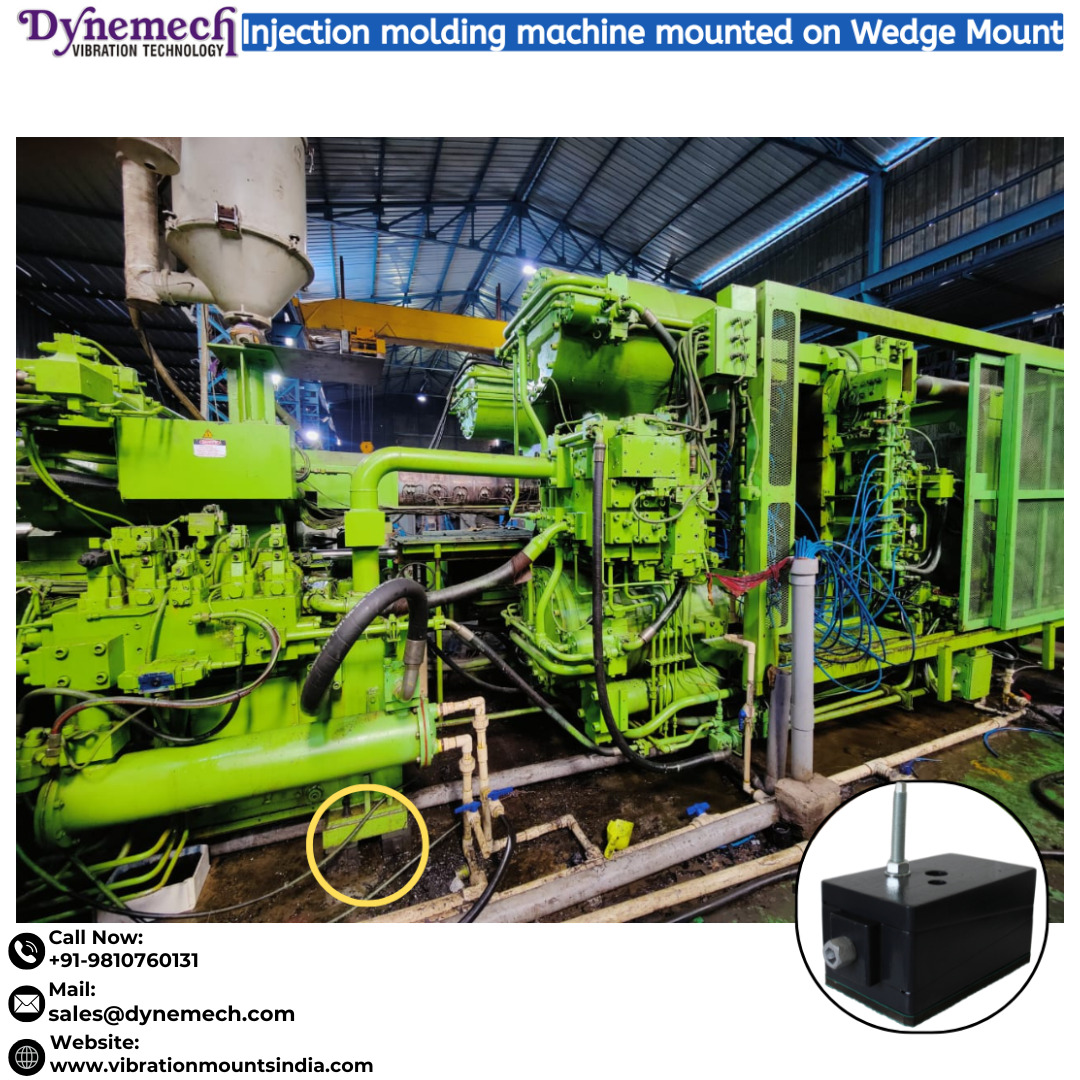

Dynemech Wedge Mounts are then of paramount importance. Our Advanced

and Sophisticated Mounting Solutions are designed specifically to increase

machine stability by cutting down its vibrational transfer and enhancing

levelling accuracy—all without complex foundation work.

Why Choose Dynemech Wedge Mounts for Your InjectionMoulding Machine?

✅ Superior Levelling &

Alignment

Dynemech Wedge Mounts provide the capability to make fine adjustments in level

to ensure through-going operational conditions of your machinery with zero

misalignment, as required for accuracy in moulding and high-standard

production.

✅ Enhanced Stability &

Reduced Vibrations

This piece of machinery, if not stable enough, can directly or indirectly

affect the internal production quality, cause rapid deterioration, and increase

maintenance costs. Our Wedge Mounts provide a rugged, stable platform that will

remedy machine movement and vibration that will hamper machine performance.

✅ Extended Machine Life &

Reduced Maintenance

One of the benefits of correct mounting is that it reduces the potential for

its components to become misaligned, thus lessening mechanical wear and

achieving lower maintenance costs in the long run. Prolong the lifespan of your Injection-Moulding Machine through the elimination of unnecessary stress on its

components.

✅ Easy Installation & No

Need for Costly Foundation Work

Dynemech Wedge Mounts, unlike traditional installation systems based on

foundations, are designed to avoid the hassle of installation. You don't even

have to make expensive modifications to your workspace. Just mount your machine

and start feeling the performance.

✅ Optimized for Heavy-Duty

Applications

The Wedge Mounts are designed for heavy load and continuous operation in InjectionMoulding Machines, CNC Machinery, Die Casting Machines, and other industrial

applications.

Achieve Peak Productivity with the Right Mounting

Solution

Dynemech Wedge Mounts represent your guarantee that

production is smooth with no minimal downtimes, hence:

✔ Seamless production with minimal downtime

✔ Consistent moulding accuracy and product quality

✔ A robust, stable foundation for long-term

operational efficiency

Put Dynemech Wedge Mounts under your Injection Moulding Machine,

and then see the difference in precision, stability, and overall performance.

New foundation, optimized productivity, reduced maintenance hassles, for what

it's worth-A strong machine indeed deserves a strong base.

🔗 To learn more about

our products: https://www.vibrationmountsindia.com/products/

#InjectionMolding, #MachineStability, #DynemechWedgeMounts,

#PrecisionManufacturing, #VibrationControl, #IndustrialSolutions, #CNCLeveling,

#HeavyMachinery, #ManufacturingExcellence, #ReliablePerformance

📞 Contact Us:

+91-9810760131

📧 Email: Sales@dynemech.com

🌐 Explore Our

Solutions: vibrationmountsindia.com

Let me know if you need any further refinements.

No comments:

Post a Comment