Dynemech

Wedge Mounts are designed for highly dynamic and precision industrial machinery

that require precision levelling, vibration absorption and fixed connection

between the isolator and the machine base.

These wedge mounts come in diverse types,

each tailored to specific applications, load requirements and vibration problem

faced. Selecting the appropriate wedge mount is paramount to ensuring the

optimal performance, stability, alignment and vibration damping in various

industrial setups.

Common Types of Wedge Mounts

1. Bolt-on Wedge Mounts

Bolt-on wedge mounts are engineered for

heavy-duty applications demanding maximum stability and load-bearing capacity

with precise levelling. These wedge mounts offer secure attachment to

equipment and with its precision levelling mechanism, aligns your machinery

like tool room machines, plastic injection moulding machines, pressure die

casting machines, shapers etc.

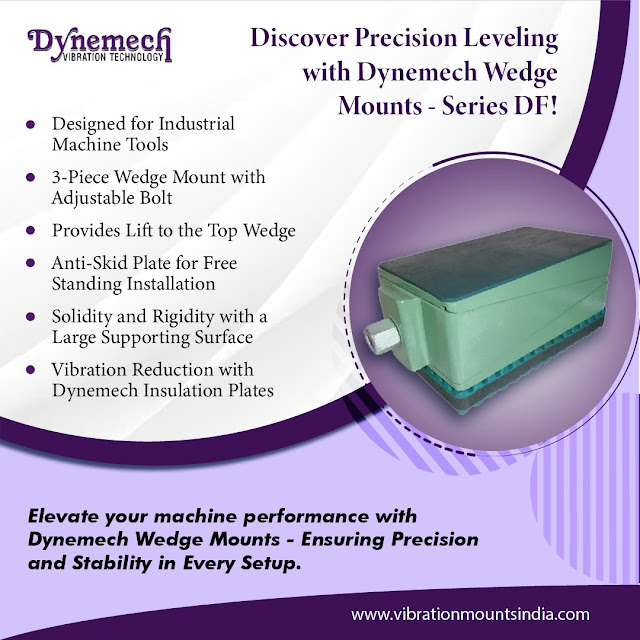

2. Free Standing Wedge

Mounts

Free standing wedge mounts are preferred

for their versatility and ease of installation. An adjustable wedge mount that

is vibration-proof and has a precise levelling mechanism, a big adjustment

stroke, and a function that prevents vibrations from occurring.

Their excellent shock absorption and

vibration isolation properties make them the go-to choice for heavy machinery

and equipment where minimizing vibrations is crucial. Fins

application in power presses, stamping machines, shearing machines, punching

machines etc

3. Bolt Thru Wedge

Mounts

An optimal selection for machines

experiencing fluctuating loads, unidirectional load bias, or significant

dynamic disturbance pressures. The Bolt thru Precision Leveller is securely

attached to both the machine and the ground, providing exceptional vibration

and impact isolation capabilities.

Incorporating special engineered

elastomers, these mounts excel in absorbing and dissipating vibrations,

offering enhanced vibration reduction capabilities. They are indispensable in

applications like pressure die casting machines, injection moulding machines,

presses, industrial pumps , stamping machines and many more

Factors to Consider When Choosing Wedge

Mounts

1. Load Capacity

Matching or exceeding the weight of the

supported equipment is imperative , prevents overloading, which can compromise

stability and performance.

2. Alignment and

Levelling

Easy alignment and precise leveling

options dictated by machinery and operational requirements. This ensures proper

alignment and reduces the risk of machinery damage due to uneven surfaces or

misalignment.

3. Vibration Isolation

Capabilities

Evaluate the degree of vibration

reduction required and select appropriate vibration isolation sheets

accordingly. Different machine , static and dynamic loads and operational

behaviour will dictate such selection.

4. Environmental

Conditions

Take into account temperature

fluctuations, dampness, chemicals, and oil or solvent exposure. To ensure best

performance and endurance, use anti vibration mounts that match your

application's environment.

Consulting with Experts for Optimal

Selection

Experts or experienced vendors should be

consulted for in situations with specific requirements.

Conclusion

Choosing the right wedge mounts ensures

equipment stability, machinery performance, and tolling / die and machinery

longevity. By evaluating load capacity, flexibility, vibration isolation, and

environmental compatibility, you may select application-specific options.

FAQs (Frequently Asked Questions)

1. What are wedge mounts

used for?

Wedge mounts are employed to offer

stability and mitigate vibrations for a diverse array of equipment, including

both robust , heavy duty presses and sensitive scientific appliances.

2. How do I determine

the load capacity for wedge mounts?

It is imperative that the load capacity

of wedge mounts be equal to or greater than the weight of the machinery being

supported to prevent excessive overloading.

3. Are anti-vibration

wedge mounts suitable for all applications?

Anti-vibration wedge mounts are highly

effective in reducing vibrations and are especially well-suited for settings

that need precision and precise alignment and levelling.

4. Can wedge mounts be

used in outdoor environments?

Indeed, wedge mounts are suitable for

outdoor settings, but it is crucial to verify their compatibility with the

current climatic conditions in order to preserve excellent performance and

durability. The working conditions of the wedge mount can match with the

working condition of machinery.

5. Are wedge mounts

reusable?

Wedge mounts are specifically engineered

to serve many purposes and may be utilised again, provided they are in optimal

condition and suitable with the machinery being supported.

#AntiVibrationMounts, #VibrationIsolation, #IndustrialEquipment

, #PrecisionEngineering,

#DynemechPerformance,

#VibrationControl,

#EngineeringSolutions,

#Dynemech,

#IndustrialApplications,

#HighQualityMounts,

#shockReduction,

#MachineryProtection,

#VibrationDamping.

Contact:

Dynеmеch Systеms Pvt

Ltd.

Mob: +91-9810760131 ;

+91-9911145131

Email: Salеs@dynеmеch.com

www.vibrationmountsindia.com |

www.vibrationdampingpads.com

No comments:

Post a Comment