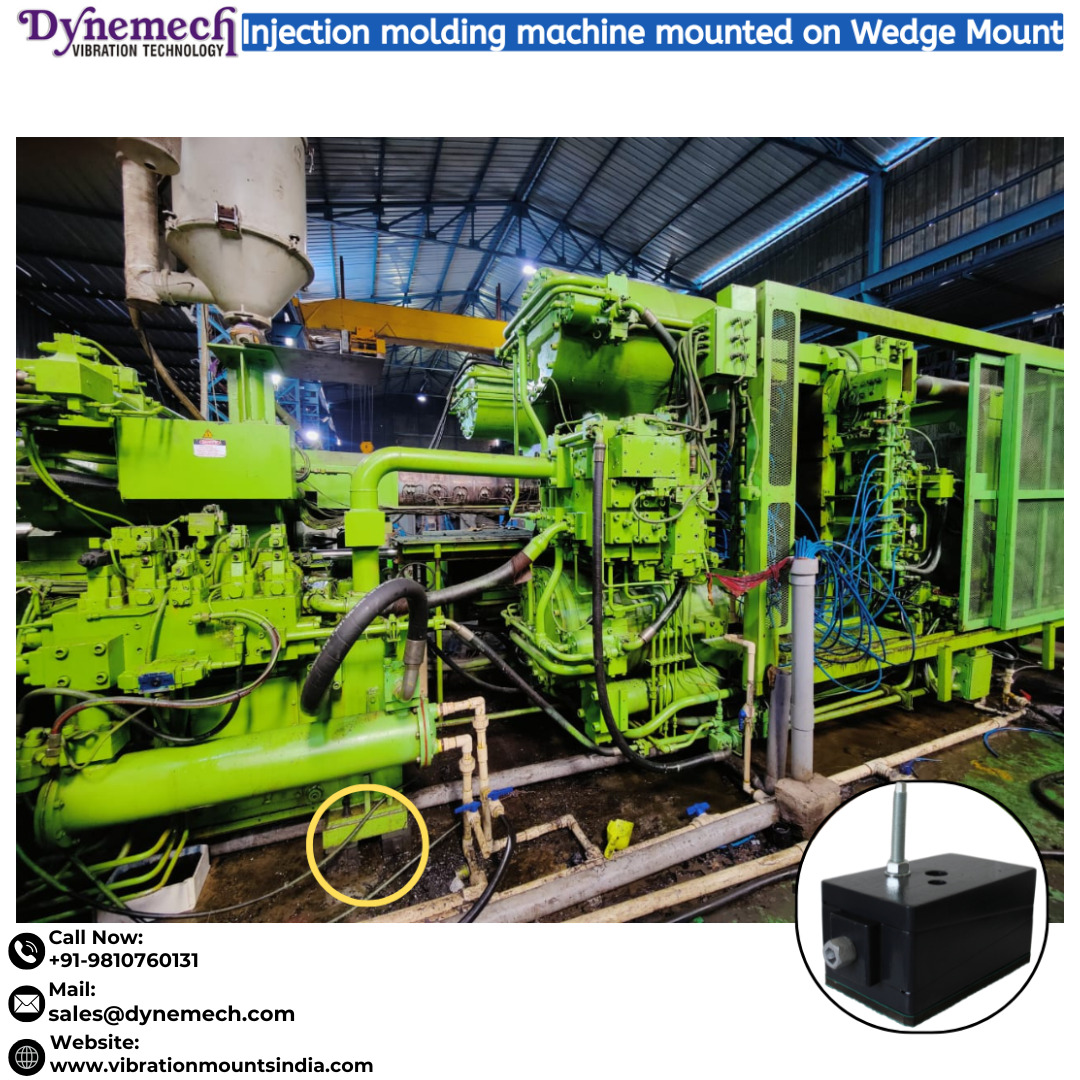

Stability and accuracy are cornerstones to

success in precision manufacturing, and Dynemech Systems Pvt. Ltd. is taking

the lead with their innovative Wedge Mounts developed specifically for CNC

turning machines. Dynemech Systems is a long-time player in vibration control

technology and offers the best that is currently available to suppress

vibration to an extent that improves machine stability, allows a machine to run

ideally at maximum rate of output, and increases equipment lifespan by removing

the source of vibration. Why Vibration Control is Important for CNC

Turning Machines

CNC turning machines are regarded as precision

instruments used to manufacture complex parts with precise tolerances in

manufacturing processes in the automotive and aerospace industries, medical

device manufacturing, and other applications. The CNC processes of high speed

and high load generate immense vibrations that can disrupt machining

operations, and when not controlled, may:

·

Negatively impact machining accuracy and

surface finish

·

Increase tool wear and component wear

·

Reduce machine reliability and durability

·

Increase operator fatigue and noise levels

Dynemech Wedge Mounts address these challenges

head-on, providing robust vibration isolation and precise levelling to ensure

CNC turning machines operate at peak efficiency.

Dynemech

Wedge Mounts: Engineered for Excellence

·

The Wedge Mounts were developed from an

awareness of how precision is affected by the structural integrity of a

machine. Other mounts may cause some vibration isolation however, the Wedge

Mount takes it to another level.

Features

·

Level of accuracy: Height-adjustable wedge assembly

allows for accurate levelling and weight distribution for high-accuracy

machining.

·

Max vibration isolation/dampening: The

high-performance dampening materials offer excellent absorption and dissipation

of vibration, limiting the effect of the machine's vibration on performance.

·

Heavy duty: The wedge mount is designed to

hold the weight and determine the dynamic loads of CNC Turning Machining

systems to offer a long, reliable service.

·

Multi-dimensional use: Wedge mounts are

versatile, useful in all types of industrial applications, from your small shop

working on lathes and mills, to a manufacturing plant supporting CNC Turning

Machining systems.

·

Quick install: The simple design of the wedge

mount allows for quick installation and adjustment, thus reducing downtime.

·

Adding Dynemech Wedge Mounts allows companies

to provide better machining accuracy, longer tool life, and a more comfortable

and quieter work environment.

By

incorporating Dynemech Wedge Mounts, companies are able to realize better

machining accuracy, longer tool life, and a more comfortable and quieter work

environment.

Industries

Trusting Dynemech Wedge Mounts

Dynemech's Wedge Mounts are the first choice

in various industries, such as:

·

Automotive Production: Providing accuracy for engine parts and transmission components.

·

Aerospace Engineering: Facilitating high-tolerance machining for sensitive aircraft

components.

·

Medical Device

Manufacturing: Ensuring accuracy for complex surgical and diagnostic

devices.

·

Metal Cutting and Metal

Forming: Improving stability for lathes, mills, and

presses.

·

HVAC and Power Generation: Offering stable support for heavy equipment in harsh environments.

·

Textile and Steel Sectors: Improving the performance of looms, rolling mills, and others.

🔗 Learn More: https://www.vibrationmountsindia.com/products/

#DynemechWedgeMounts, #CNCVibrationControl,

#PrecisionEngineering, #AntiVibrationMounts, #MachineStability,

#IndustrialMountingSolutions, #VibrationDamping, #CNCTurning,

#ManufacturingExcellence, #HeavyMachinerySupport, #EngineeringInnovation,

#AutomationSolutions

📧 Email: sales@dynemech.com

📞 Phone: +91-9810760131

🌐 Website: www.vibrationmountsindia.com

Join the countless manufacturers worldwide who

trust Dynemech to keep their operations steady, precise, and efficient. Let’s

build the future of manufacturing together!

.png)