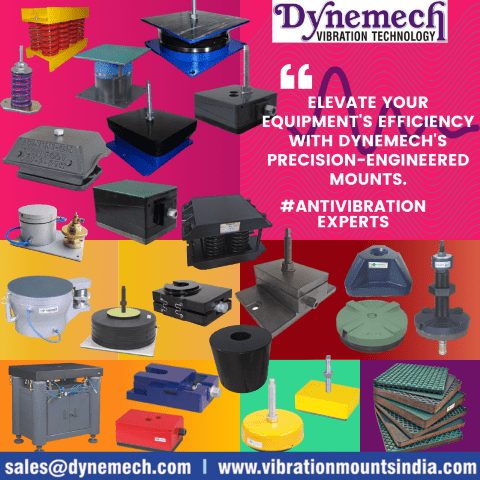

Benefits of Using Anti-Vibration

Pads for Machinery

Machinery

is an essential a part of any commercial , industrial and manufacturing

facility. However, it can produce quite a lot of disturbing vibration and

noise, that may cause damage to the equipment and affect the general

productivity of the manufacturing and industrial operation. This is where Anti

Vibration Pads for Machine pitch in. Anti-vibration pads for device are

designed to dampen the impact of the vibration and reduce the noise level of

the system. In this weblog, we are exploring the advantages of the use of anti-vibration pads for industrial equipment and

production machinery.

Wedge mounts provide stability and vibration

control without the need for bolts, ideal for precision machinery

1. Protects Equipment from

Damage

One of the

primary advantages of the usage of anti-vibration pads is that they shield the

equipment/machinery from harm resulting from traveling vibrations.

Machinery that operates at high speeds or is subject to several operational

oscillations can produce a whole lot of vibration, which could reason put on

and tear on the device over the years. Anti-vibration pads assist to take in

the vibrations and save you harm to the system.

2. Increases Equipment

Lifespan

Another benefit

of the use of vibration control mounts is that they can boost the lifespan of

the device. By reducing the impact of the vibration, the system is subjected to

much less strain and stress, which can enhance its lifespan. This means that

companies can save energy and resources on repair and maintenance and instead

focus on production efficiency.

3. Reduces Maintenance Costs

Anti-vibration

pads also can help to reduce expensive maintenance and repair bills and

increase productivity. When machinery is subjected to uncontrolled vibrations,

it may cause frequent breakdowns and maintenance issues. This additionally

leads to downtime, which could affect productivity. Saving of money, time,

productive hours are just one of the benefits of anti vibration mounts.

4. Improves Equipment/Machinery

Performance

Vibration

also affect the overall performance of the equipment. When equipment/machinery

or nearby measuring and testing equipments have difficulty in mitigating

vibrations, it may cause inaccuracies in measurements or affect the production

output. Dynemech Anti-Vibration Pads protects against both structure-borne and

attenuated vibration,ensuring the safety of sensitive equipment, heavy

equipment, or precision instruments . Anti-vibration pads assist to stabilize

the machinery, reducing risk of tipping over or becoming unbalanced, enhancing

overall performance and accuracy.

5. Quieter Workplace

Dynemech

Anti Vibration Mounts are effective for lowering the noise generated by means

of equipment/ working machinery . When machinery vibrates, it can produce

plenty of noise, which may be disruptive and uncomfortable for human beings in

the surroundings. Anti-vibration mounts absorb or dampen these vibrations,

leading to a more pleasant and comfortable workplace, not to mention

n=compliance of noise regulations.

6. Increases safety through Anti

Vibration Pads

Excessive

machinery vibration can weaken or even completely damage various parts and

components. These loose or dislodged components can lead to accidents, injuries,

or damage to the workers and machinery itself.

Dynemech

Anti-vibration mounts play an important role in increasing workplace safety by

stabilizing machinery, absorbing vibrations from within and outside the

machinery, keeping the machinery and its components in place and reducing

the risk of accidents involving loose or displaced parts. In industries where

heavy machinery is used or where accuracy is important, such as laboratories,

in production testing and calibration facilities,research, manufacturing

facilities, the use of anti-vibration mounts is an integral part to ensure the

safety of equipment and personnel.

7. Easy

Installation

Anti-vibration

pads are easy to install and can be used with a variety of equipment. They come

in different sizes and shapes, making them adaptable to all industrial machinery.

They can also be customized to fit specific equipment/ machinery, which ensures

maximum effectiveness.

Conclusion:

Vibration Mitigation is an essential component of any

industrial , manufacturing and production facility for optimal machinery

operations. They protect equipment from damage, increase lifespan, reduce

maintenance costs, improve performance, reduce noise pollution, enhance safety,

and are easy to install. By using anti-vibration pads, companies can improve

productivity, reduce downtime, and save money on equipment replacement and

repair costs. Dynemech anti vibration pads are the most effective and

cost efficient solution for achieving manufacturing efficiency.

#Vibrationmounts

#Antivibrationmounts

#Machinerymounts

#Machinevibrationmounts

#freedomfromvibrations

#Rubbermounts

#Industrialvibrationmounts

#vibrationfreesolution

#smoothwork

#cherishbuildcelebrate

Contact:

Dynеmеch

Systеms Pvt Ltd.

Mob:

+91-9810760131 ; +91-9911145131

Email:

Salеs@dynеmеch.com

www.vibrationmountsindia.com |

www.vibrationdampingpads.com

.jpeg)

.jpg)