|

Vibra Mountings -Anti Vibration Mounts |

Centerless grinders are

one of the most common tools used in manufacturing. These machines are used to

remove material at a steady yet slow pace through the process of grinding.

Centerless Grinding is equipped to grind a wide variety of studs, pins,

bolts, screws, bushings, and other parts from a full range of materials. These

machines are commonly found in manufacturing settings in aircraft, aerospace, defence,

hardware, electronics, automotive, marine & medical industries.

|

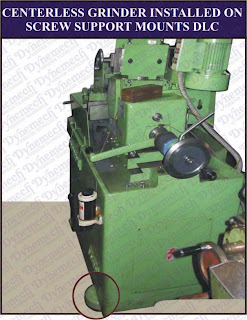

Centerless Grinder On Dynemech Vibra Mounts |

It’s the relationship

among these three basic components—grinding wheel, regulating wheel and work

blade—that makes the difference between a successful centerless grinding

application and one that gives headaches and bad parts. But, it is the same

interaction that gives rise to undesirable vibrations leading to uneven surface

finish, problem of chatter and rejection of job lots and overall loss of

production efficiency. Unbalance in spindle-collet combine, grinding wheels,

motors , bearings ,presence of outside vibration all affect the precision

grinding process. The use of centerless

grinding has now a days become imperative in shops involved in high volume

production runs.

|

Grinders -Vibration Isolation |

Forced vibration from

machine rotating elements and self-excited vibration produce a relative radial

movement between the wheel and work piece during grinding and the wheel and

diamond during dressing, causing errors in work piece finish and form. By controlling

vibration produced during the grinding and wheel dressing operations a measure

of expected work piece accuracy and quality can be obtained.

|

Anti Vibration Pads For CNC Grinders |

Over the years, Dynemech

has successfully isolated all kinds of passive vibration ie. vibrations coming

to the centerless grinder from other impact and rotating machines of the shop

floor and/or from other nearby sources. Our anti vibration solutions provide a

unique combination of value, precision, productivity and practical usability.

They also provide protection from vibrations transmission from the machines to

nearby sensitive equipments and machines, to suspended floors, walls and

buildings.

|

Centerless Grinding Machinery Mounts |

Dynemech has engineered

different anti vibration solutions for centerless grinding machine depending

upon the environments they are being installed in. Some of the scenarios are:

|

DYNEMECH Precision Leveling Mounts and fixators |

VHS with Dh insulation plate

Precision Levelling Mounts - Series VHS mounts provide

precise levelling and alignment. The top spherical plate of VHS Series

compensates for the angular difference between the machine base and the floor.

The body of the mount can be anchored to the floor to keep the mount positioned

during installation of machines over Series VHS. The levelling can them be done

after that. VHS Series mounts can be anchored to the floor or can be used as

free standing elements. VHS series wedge combined with Dh insulation plate provided

high stability along with vibration reduction.

|

CNC Machine- Vibra Mounts |

|

Leveling Jacks for Grinding Machines |

|

Vibration Control in Grinding Machines |

Our wedge mounts, Series DB

with Ds2 insulation plate is most suitable for centerless grinding machines as

it dampens vibration transmission from the machine to the floor and to the

surrounding measuring instruments. It also damps vibrations coming from outside

impact and rotating machines to the centerless grinder.

|

Vibration Damping Insulation Plates |

For critical applications like centerless machine

installation on suspended floor, during start up of the machine, the floor may

vibrate with high amplitudes. Also, in scenarios wherein high velocity, and

high amplitude shock waves are being transmitted from a power press or forging

hammers, air springs or vibration isolating insulation plates may be used.

For more details about Anti-Vibration mounts kindly contact us: