isolation vibration control noise isolators silent bloc silent blocs anti vibration silentbloc noise & vibration noise vibration vibration noise silent blocks av mount vibration shock fan mounts leveling foot vibrating washing machine antivibration mount

Thursday, 31 October 2013

Wednesday, 16 October 2013

DYNEMECH PRECISION LEVELING WEDGES

With the advent of 4 and 5 axis manufacturing, manufacturers

across the globe are always looking for reliable, larger and accurate work

holding devices to meet the current precise manufacturing requirements. Proper leveling

and alignment of machinery and process equipment is essential for long-term

performance, calibration and accuracy. With

larger bases, leveling and alignment may become a problem, thus necessitating

the use of Dynemech Leveling mounts. Proper alignment and leveling is an

absolute necessity in manufacturing industries such as automotive, printing,

aerospace, metal stamping, injection molding, machining and food processing.

|

Heavy Duty Long Bedded Boring Machines Installed on Wedge Series DT |

|

Leveling Wedges for Equipment Building |

- Fast and Easy Installation solutions that provide precision leveling and alignment

- Alignments are a crucial step in setting up a machine to cut accurate parts.

- Minimal maintenance and quick installation with minimum downtime

- Floor/foundation mounted large work holding devices/ tables can be easily leveled and aligned using Wedge Mounts, Series VHS or Series DTSP.

- Top spherical plate in Series DTSP compensates for angular difference.

- Enhanced Component Finish, Accuracy and Part Tolerance.

- The wedge design of VHS Series provides true vertical lift and eliminates lateral movement as machines are raised or lowered between machine base and the concrete floor.

- Built-in compensation for uneven areas in foundations and machine bases in Series VHS, Series DTSP(with or without anchoring options), Series DTH.

- Series DTH has a sturdy design and construction with higher leveling adjustment to meet TPM requirement.

- Suitable for heavy machines with higher dynamic loading.

- Dynemech provides wide range of solutions for both anchored and free standing machines and of varied weight carrying capacities, to suit almost all applications

|

Heavy Duty Lathe On Dynemech Wedge Mounts , Series DT |

|

Wedge Type Vibration Damping Machinery Mountings |

For more details about Anti-Vibration mounts kindly contact us:

ANTI VIBRATION PADS FOR HONING APPLICATIONS

|

Honing Machine Installed On Dynemech Wedge Mounts, Series DB |

Honing is a metal

removal process used after casting, sintering, drilling, boring, or reaming to

obtain precise bore dimension, geometry (cylindricity, roundness, straightness,

and taper) and surface finish. Though with the development of precision machining

and ultra precision machining technology, machining precision demands to

achieve sub micron level have increased, chatter is still a problem during

grinding which affects surface quality directly and reduces productivity. It is

more serious in high precision honing process in which a small vibration would

make the size or surface roughness of proposed part poor, leading to

rejections.

In general honing the

movement of the honing head is the synthesis of rotation movement and

reciprocating movement whose trajectory is a spiral curve with up and down

movement in close tolerances. With them numerous mechanical structure, rotating

and revolving parts with different mechanisms working in compression, stress

and torsion in a machine, lead to arousal of vibrations during the honing

process.

Vibrations

may also travel from external environment to Honing Machines disturbing surface

finish and accuracy of the job. Dynemech low natural frequency isolators damps

most of the incoming vibrations and allows smooth operation.

|

Honing Machine For Dynemech Wedge Mounts, Series DB |

|

Machinery Mounts For Honing Machines |

|

Vibration Reduction mounts |

Vibration isolation is

imposed to separate a dynamical system from its environment by means of

isolator/pad/mounts which has a considerably different natural frequency,

compared to the forcing frequency of the applied force.

The natural frequency

is specific for each system and is directly proportional to the stiffness and

inversely proportional to the mass. Thus, greater the mass and lesser the

rigidity, the lower the frequency will be. To reduce the rigidity of the system

as much as possible, we need to increase its elasticity. The natural frequency

is in inverse proportion to the static deflection under the weight due to

gravity. So, by creating a phase difference of vibration frequency, both passive

and vibration control can be achieved in honing applications.

DYNEMECH vibration damping pads provide:

·

Desirable Vibration and Noise Reduction

·

Fast, easy and inexpensive machine

installation

·

Enhanced and consistent component

finish, accuracy and part tolerances

·

Installation of Sensitive Equipments and

Heavy Machinery possible in the same workshop through Vibration Isolated

Foundation.

·

Installation of Machines at Recommended

Height of 100 -150mm for Easy Cleaning and Repairing (recommended by IMTMA).

·

Extended Tool And Machinery Life

·

Helps fulfill OSHA regulations on

anchoring fixed machinery to prevent walking or moving.

·

Longer tool life; less cost per piece,

higher productivity

·

Wide range of solutions for both

anchored and free standing machines and of varied weight carrying capacities;

suits almost all applications.

·

Mounts constructed from high strength

material and quality production processes

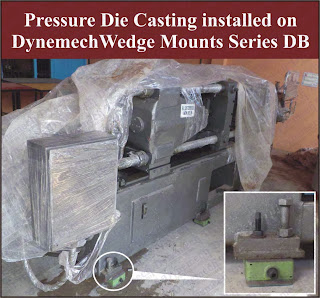

Vibration Reduction Solutions For Pressure Die Casting Machines

|

Dynemech Anti Vibration Pads for Pressure Die Casting Machines |

Pressure

diecasting is a process in which molten metal is introduced into a metal mould

or “die”, and is subjected to pressure in order that it shall conform to the

exact shape of the mould impression or “die cavity”.

Die

casting has progressed over the last fifty years from relatively small parts

made from lower melting metals and alloys such as zinc, to today’s casting of

very large parts, such as engine blocks.

As die

casting conditions grow more

severe in temperature, pressure and increased part size, increase

movement-clamping arrangements the need arises for vibration isolators to

enhance the die casting process, by providing precision levelling, alignment

and vibration control.

|

Pressure Die Casting Machine On Dynemech Isolator Mountings |

|

Dynemech Rubber Anti vibration pads |

Dynemech

anti vibration solutions help die casters to continue to advance their

operational efficiency and lower their production costs, even as the industry

faced increasing challenges for more part complexity. An increasingly high-tech, sophisticated manufacturing

method capable of superb, repeatable quality, and high production rates through

new die steels, faster die-making, computer controls and robotics can sustain

only when supported on resilient anti vibration elastomeric pads. Vibration

control thereby

·

increases quality

production

·

reduces scrap

costs

·

improved die

life, resulting immediately in longer production runs from an initial die

investment

·

reduced price per

piece and total life cycle costs.

|

Pressure Die Casting installed on Dynemech Wedge Mounts, Series DB |

Ruggedly

designed rubber mounts feature varied height adjustments and anchor free

flexible installation keeping the option of relocation of machinery open. Multiple

wedges and Dynemech insulation plates are interlocked and assembled so that

they are well suited for all applications with high horizontal forces. Besides

imparting solidity and rigidity as machine foots they provide minimal lateral

flexibility to avoid machine movement and thus mitigate vibration

transmissibility.

Precise

levelling features of Dynemech Wedge Mounts Series DF/DB ensures that the die

faces close properly, decreasing wear and tear and productivity and maintenance

issues from cropping up every now and then. The chequered cell design of the

composite material insulation plate provides skid and shock resistance besides

vibration control.

- · No machine walking

- · Variable height adjustments possible

- · Uniform weight distribution and precise alignment

- · Flexible and quick machinery installation

- Uniform distribution of uneven weights and best fitments in base square housing are some of the complimentary features that ensure ideal machinery installation.

For more details about Anti-Vibration mounts kindly contact us:

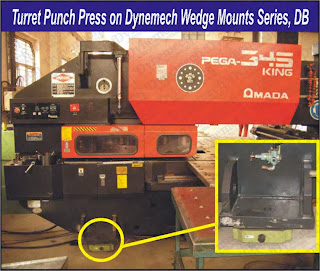

No Vibration Transmission-Turret Punch Presses

DYNEMECH-PUNCH-PRESS-MOUNTS |

Precision metal

fabricators and sheet metal components manufacturers depend on Dynemech vibration isolation

mounts for isolating their highly accurate CNC Turret

Punch Presses from vibrations.

Recognizing how

important it is to provide fast, flexible responses to customer demands, many

sheet metal pressed and fabricated components manufacturers are using the

latest CNC Manufacturing machines for the same. But, increased feed and cutting

rates also leads to increased vibration and noise. And thus, if these

vibrations hamper production accuracies or increase maintenance issues and

production cost all productivity gains are offset.

Turret-Punch-Press-on-Dynemech-Wedge-Mounts |

CNC turret punching is

a cost effective method for cutting sheet steel in moderate to long runs,

rapidly integrate processes to eliminate post operations. It has vast tooling

potential for the increased versatility translating into the ability to produce

variety of components without re-tooling.

CNC turret punch press is widely used in many varieties of sheet metal

processing industries , such as Automobile , air conditioning &

refrigeration mfg., textile & pharma machinery mfg., communications,

electronics ,computers, elevators , air conditioning, kitchen utensils ,

mechanical housings processing industries.

|

Turret Punching Press Installed On Dynemech Wedge Mounts |

|

Turret Punch Press on Wedge Mounts Series, DB8-i |

Dynemech anti vibration pads

ensure that even at maximum tonnage, vibrations are not carried over to the

table delivering increased precision and high quality parts, not to mention

improved tooling life. The electronics and laser controls is isolated from

punching vibration to help maintain beam integrity and cut quality.

In impact generating

machines like turret punches anti vibration flexible pads convert low duration

of impact in to an impulse of a longer period. Longer the natural vibration

period of the machine, isolator & foundation system, lower will be the

vibration transmissibility. Thus, vibration isolators produce a time delay and

act as a source of temporary energy storage and to some extent as a energy

damper which evens out the disturbing vibration in each oscillation. The

elastic (potential) energy of the dampers transforms into motion (kinetic)

energy of the machine and back into potential energy of the isolator, and so

on. In reality, there are always some losses of the energy (usually, into

thermal energy) due to friction, imperfections etc. As a result, the total

energy is gradually decreasing (dissipated), thus diminishing the intensity

(amplitude) of the isolated system. i.e. vibration damping.

|

Turret Punch Press on Dynemech Wedge Mounts, Series DB |

Dynemech precision

wedge mounts also provide flexible machinery installation options along with mitigation

of vibration and noise transmission from metal cutting machines to other

machines in the shop floor. To improve the vibration and noise isolation

effect, wedge mounts are usually combined with Di insulation plate having

Coefficient of friction 0.8 and natural frequency range of 25 Hz -7 Hz

depending on the load of the machine. These sturdy machine vibration

pads

limit the swift horizontal jerks caused by rapid material movement besides

vibration transmission and vibration isolation.

For more details about Anti-Vibration mounts kindly contact us:

Monday, 7 October 2013

Injection Moulding Machine Mounts

| Vibration and Shock Control in Injection Moulding Machines |

|

Dynemech Anti Vibration Machinery Mounts |

|

| Active Vibration Control in Injection Moulding Machine on Machine Mounts |

An Injection molding machine, also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. The operations in Injection Moulding Machines produce high impact forces. These forces travel through the machine frame into the foundation. The foundation produces a rebound force equal to the impact force and this travels inside the machine. The magnitude of the vibration within the Injection moulding machine is lower when using Anti-vibration machine mounts. Bolting the machine rigidly to a foundation subjects it to more vibration and impact force. Vibration isolators or machine mounts are cushions that transform a sudden shock pulse into a decaying series of longer duration forces.

Injection moulding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mould cavity where it cools and hardens to the configuration of the cavity. Injection moulding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars. To ensure higher productivity, better control, faster injection rates or better quality finished parts, Numerous automobile part manufacturers, Plastics makers, Toys makers, Aerospace, Manufacturers of Plastic Capsules and Health Related Equipments, Packing and Plumbing Equipments manufacturers turn to Dynemech range of flexible vibration control solutions ranging from DYNEMECH INSULATION PLATES, Die Cushion Pads, Wedge Mounts, Screw Support Mounts, Economical Mac Level Series DML, Series DLM/DLMS which help us to install machines even on uneven surfaces and the recently developed DLK series.

|

Anti Vibration Pads for Injection Moulding Machines |

Dynemech Injection Moulding Machine Mounts with Elastomeric Pads offer many benefits:

1. Increased equipment life.

2. Installation Savings - Machines are installed faster and easier.

3. Simplified machine installation.

4. Precision Levelling and alignment of machine mounts reduces machine wear and tear & increases tool life

5. Machine "walking" prevented.

6. Different products/customized solutions available.

7. Reduced shock and vibration.

8. Simple integration into the production plant due to flexible installation.

9. Elimination of anchor bolts. Machine can be easily re-located and Re-Levelling is much faster and easier.

10. Better Structural Safety.

1. Increased equipment life.

2. Installation Savings - Machines are installed faster and easier.

3. Simplified machine installation.

4. Precision Levelling and alignment of machine mounts reduces machine wear and tear & increases tool life

5. Machine "walking" prevented.

6. Different products/customized solutions available.

7. Reduced shock and vibration.

8. Simple integration into the production plant due to flexible installation.

9. Elimination of anchor bolts. Machine can be easily re-located and Re-Levelling is much faster and easier.

10. Better Structural Safety.

Anti Vibration Pads for Injection Moulding Machine |

Sunday, 6 October 2013

Dynemech Vibration Control Solutions for Press Brakes

|

DYNEMECH installs press brake on Wedge Mounts Series DB |

|

Press Brake on Single Spring Isolator |

|

Press Brake on Dynemech Wedge Mounts |

Dynemech vibration isolation mounts ensure faster production with minimum initial installation costs and control vibrations hence, improving die and machine life.

|

Viscous Spring Dampeners for Press Brakes |

|

Dynemech Anti Vibration Mounts |

Also, it needs to be noted that vibration isolation of machinery to prevent the transmission of vibration and noise has become one of the pre requisites to modern workshop building and layout planning. Light weight construction and the need to install mechanical equipment on upper floors, adjacent to quiet areas makes it imperative to control vibration. Furthermore, rising space rentals many a times, necessitates developing testing and quality control labs nearby sheet metal fabrication shop floor. Thus to ensure productive profitability from our machinery we must focus on vibration damping.

|

Press Brake Supported on Dynemech Wedge Mounts |

Dynemech has successfully installed many press brakes on wedge mounts to ensure flexible installation, improved machinery performance, excellent vibration damping along with precision alignment and levelling. High coefficient of friction of assembled insulation plates prevent “machine walking” to adhere to OSHA criteria for machinery installation. And of course, our anti vibration pads are ROHS-compliant and are exported to many countries.

For more details about Anti-Vibration mounts kindly contact us:

Friday, 4 October 2013

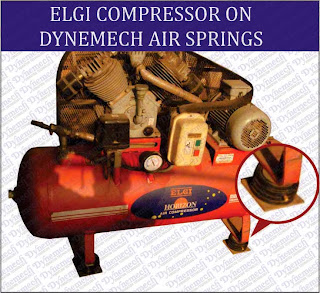

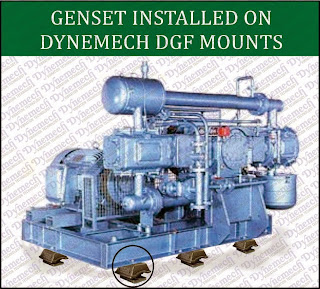

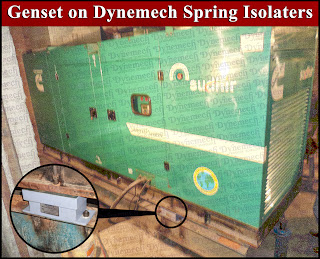

ISOLATE IT ! NO VIBRATIONS FROM COMPRESSORS & GENSETS

|

| Anti-Vibration Pneumatic Mounts for ELGI compressor installation |

unbalance in rotating parts, worn or bent gears, damaged bearings, misaligned couplings or bearings,

electromagnetic forces, etc.In compressors, however, the most common causes of vibration are unbalance in rotating/ reciprocating parts and abnormal aerodynamic forces. Vibration is a form of wasted energy that reduces the efficiency of the compressor and leads to greater vibration emissions.

|

| Compressor installed on Pneumatic mounts for vibration isolation |

Compressor installed on Pneumatic mounts for vibration isolation

Compressors are most commonly used applications in refrigeration systems, air conditioning units and

compressed air filling systems.

|

| Vibration Control in 50 H.P. Compressor installed on Dynemech Spring Isolators |

|

Dynemech Vibration Damping Insulation Plates |

|

| Vibration Damping for Compressors on Series DML |

|

| Vibration Control in Compressors on Dynemech Screw Support mounts with Levelling Adjustment |

In compressors, generators, pumps, and blowers low frequency vibration caused by flow instabilities create excitations in the supporting structures. This leads to damage to near by industrial applications and buildings. Moreover, high residual frequency vibrations caused by various rotating equipments running at varied natural frequencies may result in resonance in compressor body. Avoiding this becomes imperative for successful running of compressor units at any profitable efficiency parameters.

DYNEMECH anti vibration pads and mounts relieve stresses on the equipments thereby reducing maintenance costs. Also, it improves ambient environment contributing to a more comfortable and productive workspace. Attention to a relatively small, inexpensive vibration isolator during initial installation of compressors could prevent much more costly trouble later.

Elastomeric Mounts, Series DLK are versatile,compact and inexpensive effective vibration dampers.

|

COMPRESSOR ON Series DLK |

dimensions, robust design and excellent performance.

|

Flexifoot for Generator Support and Vibration Damping |

industrial equipments upto 80-95%.

|

High dynamic vibration damping |

Subscribe to:

Comments (Atom)